Welcome to the Wood Pellet Association of Canada’s Spring 2024 newsletter. We hope you enjoy reading it and we welcome your feedback.

This Quarter’s Headlines

At the Wood Pellet Association of Canada we are constantly seeking ways to be ahead of the curve. That’s why we expend a significant amount of our time building partnerships that leverage our collective strengths and collaborate on R&D to position our sector for long-term success.

We’ve been fortunate over the years to have strategic and mutually beneficial partnerships across the country, as well as support from provincial and federal governments for our research and development activities.

In 2023, we spent considerable effort to develop proposals that will enhance our reputation as a safe, reliable and responsible supplier of wood pellets both globally and domestically. I’m proud to say that because of this work, we are advancing six major research and development projects in 2024.

- Integrating Process Safety in Pellet Manufacturing

- Enhancing Traceability

- Exploring New Biomass Pathways

- Agri-Pellet Production Potential

- Consistent & Technically Sound Standards

- Reducing GHGs and Enabling a Net Negative Future

I want to acknowledge the tireless effort and vision of my colleague Dr. Fahimeh Yazdan Panah, Director of Research and Technical Development. On behalf of WPAC and all our members, she has led the development of these proposals alongside partners, nationally and internationally. I also want to recognize the support of our funding partners who share our vision that investments in R&D are critical not only to the long-term success of our sector but hold the key to unlocking a world of possibilities and a better future for all.

You can read more about these important research activities here.

The Wood Pellet Association of Canada (WPAC) was invited to moderate a session at the European Pellet Conference in Wels, Austria, in March 2024. Leading international speakers presented the latest market trends, policies, technologies, and innovations, providing an important avenue for Canadian pellet producers and associations to stay on top of developments in the pellet and bioenergy world.

This year’s conference focused on regaining the acceptance of pellets as an important element in the clean energy transition and increasing their positive contribution to forest health and the circular economy.

Experts also discussed new results of R&D projects and the latest developments in the pellets and bioenergy sector: technological innovations along the value chain from pellet production, supply, and distribution to successful showcases for an accelerated energy transition.

Read the full article.

Read my 2024 European Pellet Conference Trip Report for more information on the conference.

In March 2024, the Wood Pellet Association of Canada (WPAC) and some of its members visited Taiwan on a trade mission, visiting prospective customers and their facilities and participating in a one-day conference on exploring the potential of the Taiwanese market. WPAC, the Canadian Trade Office in Taipei and the Taiwan Bio-energy Technology Development Association organized the mission.

Taiwan is expected to import significant quantities of wood pellets to meet its green energy production goals. The Taiwan authorities’ commitment to generating sustainable bioenergy by using wood pellets could create a $450 million CDN wood pellet trade opportunity.

Canada is well-positioned to become a reliable supplier of high-quality, sustainably-produced, climate-friendly wood pellets to Taiwan. We can offer Taiwan advice on several fronts, including safe transportation and storage of pellets, logistics solutions, and policies supporting further uptake of wood pellets.

Read the full story and the mission report here.

The Wood Pellet Association of Canada (WPAC) was invited to speak at a seminar hosted by the Northern Sparsely Populated Areas (NSPA) in Brussels, Belgium, on October 25, 2023, focusing on the European Deforestation Regulation. More than 40 delegates from Belgium, Canada, Finland, the Netherlands, Norway, Sweden, the United Kingdom, and the United States attended the seminar at the North Norway European Office, East & North Finland.

I was honoured to be invited to attend the event as an expert speaker where I joined EU decision-makers and bioeconomy stakeholders and authorities to share perspectives and discuss the broad implications of the legislation and possible outcomes. Canada was the only non-Nordic nation invited to sit on the expert panel.

The EUDR is set to be implemented by December 2024, which means the Canadian pellet industry has a little over a year to develop the necessary computing tools to comply with geolocation requirements.

Read WPAC trip summary.

The Wood Pellet Association of Canada has updated its website to reflect our continued growth and evolution. Pellets have become mainstream around the world and are making a difference in our green energy future here at home, and our story has never been more important to tell.

In just a decade, our sector has become one of the largest pellet producers in the world, supplying customers domestically and globally with quality pellets that support a low-carbon economy. Our new website is a key tool to help WPAC and its members share their commitment to supplying the world with responsible and renewable clean energy.

The website’s modernization brings improved functionality so it’s easier for you to access the resources you need by searching for the latest research, reports, fact sheets, videos, and webinars on wood pellets. Safety is front and centre for easy access to the latest news, initiatives, and events to keep employees safe.

Our new website will continue to support the increased demand for Canadian wood pellets by advancing their contribution to the fight against climate change and to new and innovative bioenergy and biomass products. Be sure to check it out at www.pellet.org!

The Forest Enhancement Society of BC (FESBC) is funding 61 projects in communities throughout the province in 2023 that include 19 projects, announced November 30, 2023, which are supported by funding from the Province of British Columbia. These projects will reduce wildfire risk, lower greenhouse gas emissions, and provide recovered fibre to mills and bioenergy facilities.

“Improving utilization of wood fibre is a win for people and our forests,” emphasizes Gordon Murray, Executive Director, Wood Pellet Association of Canada. “These projects support the conversion of what was once considered waste into wood pellets, creating jobs, heating and powering Canadian homes and businesses, reducing wildfire risk, and contributing to global climate goals by displacing fossil fuels and advancing new technologies like bioenergy with carbon capture and storage.”

Wood pellets play a key role in helping communities create robust, sustainable economies while addressing the challenges of balancing economic development with conservation and community values, with safety at the forefront.

Aligning with the provincial government’s goal to decrease the burning of slash piles and increase the utilization of wood fibre that has traditionally been wasted, the Osoyoos Indian Band (OIB) and Mercer Celgar (Celgar) are collaborating to rethink conventional practices. With funding from the Forest Enhancement Society of BC (FESBC), the collaboration is helping recover as much uneconomical residual fibre as possible from the OIB’s traditional territory.

This collaborative project is a strategic effort to capture all low value fibre that typically wouldn’t make its way to sawmills and was not economically feasible for non-sawlog products. For example, some of the fibre captured through this project will produce wood chips, and the material not suitable as chips will be used in a product called hog fuel, which will be used to generate electricity. Some of the residual fibre will be chipped in Midway, B.C. and then sent to the Mercer pulp mill in Castlegar.

Gordon Murray’s path from a forestry operations manager to an acclaimed leader in the bioenergy sector as executive-director of the Wood Pellet Association of Canada (WPAC) reflects a career marked by significant transitions and a passion for sustainability.

Murray was honoured as the 2024 Champion of the Year at the Canadian Biomass Awards.

“I didn’t deliberately seek this position, but I rapidly grew an enormous passion for bioenergy and have been thrilled to be part of our industry’s growth and success,” he said. “The world needs bioenergy. It is a vital part of the tools needed to combat global warming,” he asserts, ready to advocate for bioenergy’s role in sustainable practices.”

Safety First Focus

Over 100 people from across Canada participated in the online Drum Dryer Symposium on April 4, 2024, to hear from producers and subject matter experts on their learnings and experiences, the current state and new approaches to drum dryer safety.

Over 100 people from across Canada participated in the online Drum Dryer Symposium on April 4, 2024, to hear from producers and subject matter experts on their learnings and experiences, the current state and new approaches to drum dryer safety.

Drum dryers present the risk of fires and explosions due to combustible dust, as well as conditions that can lead to the generation and accumulation of combustible gas. The symposium included presentations from producers and subject matter experts on learnings and experiences, the current state of and new approaches to drum dryer safety.

One of the symposium’s outcomes was establishing a Drum Dryer Working Group. Over the next year, the group will work collaboratively to examine trends, identify opportunities for improvement, and formulate recommendations. Resources will be created and shared to help support the continuous improvement of drum dryers and enhance the sector’s safety culture.

WPAC is looking for members to join the Drum Dryer Working Group. The group is expected to meet monthly for the next year and will support the development of resources shared with the entire industry. If you are interested in joining the group, please contact Fahimeh Yazdan Panah at fahimeh@pellet.org.

This event was hosted by WPAC in collaboration with the BC Forest Safety Council (BCFSC) and Canadian Biomass, the Media Sponsor.

Visit the Drum Dryer Initiative on our website for updates.

Watch the Drum Dryer Symposium.

In December 2023, more than 70 participants met in Tokyo for a full-day workshop—Safer Biomass Handling and Silo Operations: Preventing Fires and Explosions. Participants included operators, engineers and maintenance personnel from electric power stations, trade association representatives, researchers, equipment manufacturers, and wood pellet producers from Japan and around the world. Conducted in English and Japanese, the workshop was hosted by the Wood Pellet Association of Canada (WPAC), FutureMetrics, and media partner Canadian Biomass.

The workshop was held in response to customer inquiries requesting best practices to reduce or prevent future incidents and restore trust. Silo fire prevention and suppression requires a unique approach. Risks include combustible dust, structural collapse, and smoulders that can result in fire and explosions.

Read the full article here.

Click here for the presentations available in English and Japanese.

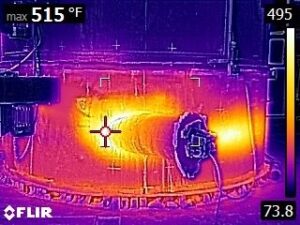

Shaw Renewables has created a monitoring system and process to improve the reliability of burner refractory which is critical for energy efficiency and performance, as well as for the safety and integrity of the burner. A refractory breakdown can lead to unplanned shutdowns, repairs, downtime, and hot spots or deterioration of the external steel shell.

The company has implemented this innovative approach at its Belledune, New Brunswick and Hardwood Lands, Nova Scotia plants. Michel Boudreau, Production, Operation and Maintenance Manager, presented this project during the Wood Pellet Association of Canada’s (WPAC’s) monthly Safety Committee meeting.

The issue encountered at the plant was numerous random refractory failures and hot spots. The team needed a way to examine and determine the condition of the refractory, as well as understand how conditions within the burner, such as combustion and air flow, impact refractory condition.

Read the full article.

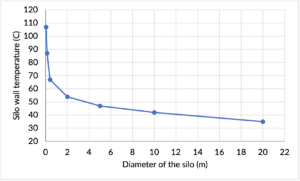

Self-heating is one of the leading causes of fire and explosion in storing wood pellets. According to the 2021 Combustible Dust Incident Report, five fire and explosion events occurred in wood storage facilities in 2021, and most recently, in 2023, self-heating led to a fire in Japan’s Yonago biomass-fired power generation plant.

These types of incidents are believed to be initiated by a temperature rise caused by moisture adsorption and condensation. The temperature increase is then accelerated when an oxidizable material, such as woody biomass, reacts to produce heat, which accumulates to a temperature of ignition and combustion. Self-heating is dangerous because when it is not controlled, fire and explosion can occur in biomass storage facilities and cause damage to health and property.

Over the past 20 years, researchers at the Biomass & Bioenergy Research Group (BBRG) at the University of British Columbia have carried out self-heating research, in parallel with off-gassing research. The research was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC) and the members of the Wood Pellet Association of Canada (WPAC). Based on our research, we have developed six key steps pellet producers can take to prevent self-heating events.

You can learn about the six key steps here.

The Wood Pellet Association of Canada (WPAC) places the highest priority on the health & safety of employees and treating forest workers fairly. It’s in our sustainability statement and in our 2024 Safety Committee Workplan. It is also reflected in our common understanding that the best way to achieve our safety goals is through a focus on strategic initiatives, effective communications, and sharing new developments and learnings in our industry for both continuous improvement and overcoming challenges.

Since 2014, WPAC’s Safety Committee has set out an annual workplan to undertake strategic initiatives that reflect the needs of members and emerging trends.

This Year’s Outlook

WPAC members continue to provide their time and expertise to collaborate as a collective industry and undertake an ambitious Safety Committee Workplan for 2024. Key initiatives include:

- Process Safety Management (PSM).

- Mobile Equipment Safety.

- Improve Drum Dryer Safety.

- New WorkSafeBC Combustible Dust Regulations.

- Industry-wide Safety Summit.

Read the full 2024 WPAC Safety Committee Workplan.

Congratulations to Premium Pellet’s Buddy (William) Berg and Cody Braun, who tied to become the first Safety Heroes to be recognized by the Wood Pellet Association of Canada (WPAC). Each have made significant contributions to making the workplace safer and better for others.

Both Buddy and Cody are members of the safety-centered team at Premium Pellet who consistently step-up to help the wood pellet industry and other frontline workers to ensure leading safety practices are implemented and embraced.

Let’s keep recognizing the efforts of our colleagues who ensure we all go home safely every day. By acknowledging this work, we are reconfirming our commitment to safety and raising awareness of the actions we can all take—big or small —every day to make our sector safer.

Read the full article about Premium Pellets Safety Heroes.

Nominate a Safety Hero online.

Last fall, more than 50 participants from wood pellet producers, operators, suppliers, and regulators from across Canada met to discuss evolving trends and regulatory topics.

The summit provided an update on current safety initiatives that are creating a safer foundation for our industry. We heard from operators about their key learnings and experiences to date and identified priorities for 2024.

We also examined future trends in safety, such as process safety management (PSM), how it will impact the way workplace hazards are handled, and what the industry can do to be prepared for new PSM regulations.

On the second day, participants attended a WorkSafeBC workshop about the Human Factor Approach to Safety and the 7-step Methodology to Improve Worker Interactions to Drive Safety.

This event was hosted by the Wood Pellet Association of Canada’s (WPAC’s) Safety Committee, in cooperation with the BC Forest Safety Council (BCFSC), WorkSafeBC, and media partner Canadian Biomass. We gratefully acknowledge WorkSafeBC for its generous funding of this program.

Download the Presentation.

Download the Report Summary.