Shaw Renewables Develops Data-Driven Process to Improve Burner Safety

Shaw Renewables has created a monitoring system and process to improve the reliability of burner refractory which is critical for energy efficiency and performance, as well as for the safety and integrity of the burner. A refractory breakdown can lead to unplanned shutdowns, repairs, downtime, and hot spots or deterioration of the external steel shell.

The company has implemented this innovative approach at its Belledune, New Brunswick and Hardwood Lands, Nova Scotia plants. Michel Boudreau, Production, Operation and Maintenance Manager, presented this project during the Wood Pellet Association of Canada’s (WPAC’s) monthly Safety Committee meeting.

The Belledune facility continuously operates 24/7/365 and produces 100,000 tonnes per year of bulk pellets shipped through the Port of Belledune. The Belledune plant uses a 75 MBtu vertically stacked, single wall suspension burner.

The issue encountered at the plant was numerous random refractory failures and hot spots. The team needed a way to examine and determine the condition of the refractory, as well as understand how conditions within the burner, such as combustion and air flow, impact refractory condition.

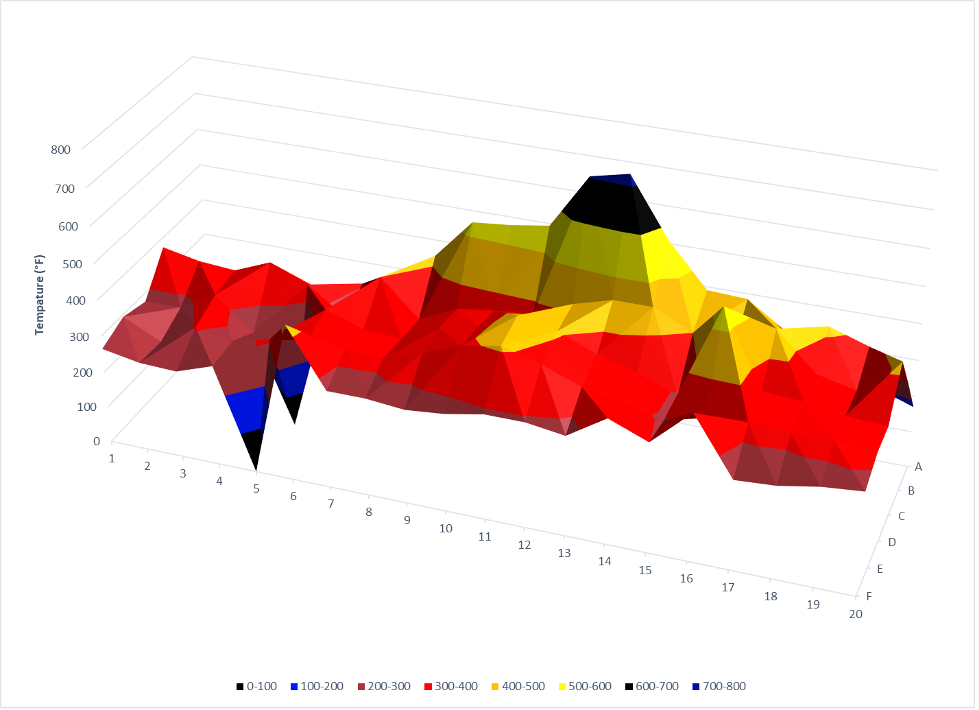

The engineer responsible for site maintenance, Brad Matthews, worked with a Université de Moncton, summer student, Frederik Boudreau, to develop a tool for refractory predictive maintenance involving monitoring of the skin (outside) of the biomass suspension burner. This tool involves collecting skin temperature every day, which is tracked in a user-friendly spreadsheet.

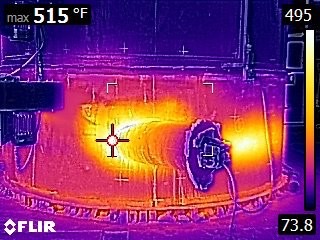

A grid for systematically and consistently measuring each key area of the burner skin was developed, and other influencing parameters, including fuel type and operating set points, are also documented. The data is then analyzed daily—using a model that involves the relationship between the skin temperature and burner temperature, the remaining refractory thickness can be determined. The use of high-definition thermal cameras to help with data collection and process control has also been incorporated.

“I’m very pleased with the success of this tool and the collaborative ‘six sigma-like’ approach by the team in its development,” said Michel. “It gives us a very good predictive maintenance tool and led us to purchase a surveillance infrared thermal camera which monitors and records burner skin temps 24/7 with real time display and alarms to the control room.”

Introduced in 2022, the initiative has yielded several important benefits:

- Allows the plant to schedule preventative maintenance to proactively fix refractory and prevent hot spots.

- Improves reliability of the burner.

- Predicts any upcoming refractory failures.

- Maximizes the burner’s efficiency through temperature control improving overall productivity.

- Helps monitor changes and improvements of the burner; with the first improvement implemented in August 2023, which was a fuel diffuser.

The tool was also integrated at the Hardwood Lands facility with the help of a Dalhousie University Co-op student. This problem involved working with the team collaboratively, working outside the box, and being creative to produce this innovative solution. Experience was important here because it was not a standardized methodology or solution. Michel indicated that his previous experience in mining, metals, and sawmilling helped provide the foundation for focusing on this approach. He also points to buy-in at all levels of the company and clear communications as critical factors in the initiative’s success.

The tool was introduced to the team at a weekly toolbox meeting. From there, daily temperature checks were added to the Assistant Operator’s daily tasks. Data collection was simplified and completed manually and later entered into a spreadsheet that graphs the data. The employees were initially surprised and impressed with how the data can be used to provide more insight into the process—the ability to see the temperature data graphed out as an image really tells all.

Kayleigh Rayner Brown, MASc, P.Eng., is a Director with Obex Risk.

WPAC’s Safety Committee’s mission is to improve the wood pellet industry’s collective safety performance, to earn a reputation with regulatory authorities and the public as an industry that is highly effective at managing safety, and to learn and share best practices regarding safety.