Welcome to the Wood Pellet Association of Canada’s Fall 2023 newsletter. We hope you enjoy reading it and we welcome your feedback.

This Quarter’s Headlines

By Gordon Murray, Executive Director, WPAC

Do you know it’s been 25 years since our first shipment of pellets from Canada? What might have seemed like a pipe dream is very much a reality. Today, Canada’s pellet sector is a global powerhouse not just in producing pellets but in the global fight against climate change. We’ve taken what was niche and moved mainstream.

And so, how did we get here? While it’s the collective efforts of companies, employees, suppliers, customers and others, it all started as the brainchild of one man: John Swaan, also known as the “godfather” of the pellet sector.

It began with John’s idea of taking the wood waste residues from Northern B.C. sawmills and, instead of burning the shavings and sawdust in bee-hive burners (as was standard practice at the time), turning them into wood pellets. He planned to sell them in the growing Seattle market.

By 1994, as Pacific Bioenergy, he negotiated a partnership with the Carrier Group, to build one of Canada’s first stand-alone wood pellet plants. Unfortunately, when the plant opened, the heating pellet market in Seattle crashed. John negotiated a verbal commitment from a big box store for 15,000 tons of bagged product a year, but it fell through and now he had 9,000 tons of bagged product in the plant’s yard with no home for it.

As the saying goes, necessity may be the mother of invention, but desperation is the mother of creativity. With 9,000 tons of pellets, John began looking for options.

He identified Sweden as a potential market for his pellets. But there were a few logistical challenges to work out … like a train, a vessel, a port … and how to get the pellets from Prince George to Sweden.

Using his connections, John found an unused conveyance system and terminal in Prince Rupert. The company had storage at the terminal, but only 6,000-7,000 tons, so almost 10,000 tons had to be stored in railcars. So John contacted CN Rail, who had a rail line to Prince Rupert. He negotiated a rate agreement and monthly lease with terms that were good by today’s standards. Working with a Swedish Canadian, Staffan Melin, they were able to convince an Asian shipping company to take on a bulk cargo of wood pellets. At the time, no one had moved wood pellets this way. The fact is that John risked everything to send a single shipment to Sweden.

“If it weren’t for John—his determination and his knowledge and expertise—we wouldn’t be where we are today,” says Vaughan Bassett, Past President of WPAC and Senior Vice President Sales and Logistics at Drax PLC. “He didn’t launch just a vessel he launched a new sector, one that has gained global support as a clean, renewable and responsible source of energy and is making a positive difference in our forests, our communities and in the fight against climate change.”

The fact is John’s expertise is hard won and a combination of many tough lessons along the way that have been forged out of determination in the face of desperation; these lessons have helped to create and support the multibillion-dollar wood pellet industry we all know today.

We recently paid tribute to John at our annual WPAC Conference September 19-20 in Ottawa. But with a conference theme of Biomass is Mainstream, The Next 25 Years: Opportunity & Innovation, we didn’t just look back, we looked forward.

The next generation of products will shift traditional views of wood pellets. That means giving Canadians more choices when it comes to renewable energy; in Europe it means taking the wins we’ve seen on the commercial and residential side to more industrial heat and displacing the reliance on Russian natural gas; and in the United States, it’s flying planes with sustainable aviation fuels and globally supporting the transition to green hydrogen and ammonia. In Europe and Japan, we can turn older coal plants into co-firing so they, too, can benefit from the flexibility that wood pellets provide.

While our export markets will always be important, we are turning our focus to here at home to provide a responsible solution to local energy needs where coal, oil and other fossil fuels are still being used. Making the shift from oil and coal-based heat and electricity to wood pellets in Canada will take three simple steps: the right policies, strong incentives, and effective communications. In Canada’s North and the Maritimes, there is already a shift to renewable energy for both commercial and home applications. We need to continue to support this evolution by working together with governments and agencies to encourage biomass use.

With all these opportunities, our ability to meet the growing demand for wood pellets will require stable access to fibre, ongoing investment, a strong logistics network, the right equipment, safe workplaces, and the right people. Our people are the foundation of our success. WPAC is committed to being among the most inclusive and successful trade associations by actively seeking diversity across the industry.

The Canadian wood pellet industry has a critical role to play in the global fight against climate change. I look forward to seeing what ingenuity the Canadian biomass industry brings over the next 25 years. With the planet getting hotter and climate disasters worsening, if there ever was a time to be creative, it’s now.

The Wood Pellet Association of Canada’s annual conference began with an unusually sentimental note this year: a tribute to the “godfather of wood pellets”—John Swaan. This year marks a quarter century since Swaan orchestrated the world’s first bulk shipment of wood pellets from his B.C. pellet mill to a customer overseas.

“It’s an honour to be singled out,” Swann told the conference crowd. “It took a village… I’m very proud to be involved in helping seed some milestones that have come along.”

Twenty-five years later and the pellet industry is thriving coast to coast in Canada, providing a market for low value sawmill and forestry residuals.

The stimulating two-day conference in Ottawa, September 19 to 20, featured speakers from around the world who inspired and challenged our sector to:

- Celebrate how far we’ve come and set the stage for the next generation of products and solutions.

- Explore conditions driving record growth for the pellet sector for a look at what’s ahead for Canadian pellet producers.

- Discuss what diversity and inclusion should look like in our sector with the people and communities who are the foundation of our success.

- Discover the next generation of technologies in biofuels in readiness to seize the opportunities ahead.

Keynote speaker Bruce Lourie, president of the Ivey Foundation and climate policy expert, wrapped up WPAC’s 2023 conference with an honest review of Canada’s emissions targets versus results. He pointed out that among the G7 countries, Canada is well behind counterparts with oil and gas largely exported and those emissions “owned” by us.

“We have to do more than we’ve committed, and we have to get done what we’ve committed to,” Lourie said.

For the pellet industry, he suggested that policy makers and the public will be more convinced by the importance of the industry to jobs, health, and family than to emissions reduction. “That’s what people really care about,” he said, “it’s an economic and community story.”

To view presentations, click here.

The UK government’s recently released Biomass Strategy 2023 defines the government’s position on sourcing and using sustainable biomass. The Wood Pellet Association of Canada (WPAC) supported the development of this strategy by responding to the UK government’s call for evidence as it reaffirms the UK’s commitment to sustainable biomass.

The Strategy outlines the potential role biomass has in power, heating and transportation, for the short, medium, and long term. This includes bioenergy with carbon capture and storage (BECCS), which is key for meeting net zero targets as it can provide large-scale carbon removal.

In the UK, 66 percent of biomass used in renewable energy generation comes from domestic sources, the rest from international sources. Both are expected to support biomass use across the UK economy. Canadian wood pellet producers look forward to working with its customers and partners to support the UK’s long-term environmental goals and renewable energy needs.

To read the full article, click here.

On December 14, 2023, the Wood Pellet Association of Canada (WPAC) will be sharing its safety expertise in person in Japan to reduce the risk of silo fires. The full-day workshop will be presented in English with simultaneous translation in Japanese, and will cover safer biomass handling and silo operations to prevent fires and explosions.

Focusing on both prevention and response to silo fires, this important workshop will be of interest to anyone in the industry using silos, bins, bunkers, or other bulk storage vessels to store biomass fuels such as wood pellets, wood chips and PKS. It will also be highly relevant to first responders who may be called out to respond to silo fires.

WPAC’s Gordon Murray, Executive Director will moderate the workshop, which features presentations by John Swaan of FutureMetrics and WPAC’s Kayleigh Rayner Brown.

Topics include:

- Biomass handling and storage considerations

- Causes of silo fires and explosions

- Biomass ignition prevention

- Silo firefighting techniques and procedures

- Personnel safety

- Fire prevention methods

- Preventative and preparatory measures

- First responder training

- Case studies

To learn more, click here.

safety news

The Wood Pellet Association of Canada (WPAC) and the BC Forest Safety Council (BCFSC) have released a new report that summarizes the key actions plant operators can take to manage the risk of combustible gas in drum dryers.

In wood pellet production, there is the potential for the formation and ignition of combustible gas, primarily in dryers and burners. Combustible gas, also known as synthesis gas or syngas, is a mixture of flammable hydrocarbons and volatiles (such as methane), carbon monoxide and hydrogen. It is formed when biomass is heated in low-oxygen environments and can accumulate in enclosed areas, like dryers, ducts, cyclones and piping. Ignition of combustible gas can lead to explosions that cause injuries, facility damage and production downtime.

The report, Combustible Gas Risk Reduction in Wood Pellet Production Drum Dryers, is a result of a bow tie analysis workshop conducted in collaboration with staff at Premium Pellet in Vanderhoof, British Columbia and Kayleigh Rayner Brown, MASc, P.Eng. (Obex Risk Ltd.). Bow tie analysis is a hazard analysis tool that wood pellets and medium-density fibreboard manufacturers have previously used to evaluate combustible dust hazards.

To read more, click here.

By Kayleigh Rayner Brown, MASc, P.Eng. (Obex Risk Ltd.)

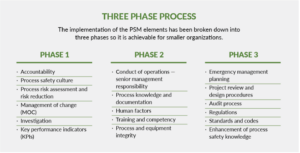

The Wood Pellet Association of Canada (WPAC), BC Forest Safety Council (BSFSC), Dalhousie University, and DustEx Research Ltd., along with Obex Risk Ltd. as project technical lead, recently completed a research project to look at the implementation of process safety management (PSM) using the CSA standard Z767 Process Safety Management as the framework.

Around the world, PSM is becoming central to worker safety and managing risk. It can help prevent fires and explosions to protect personnel, operations, and production. Safer operations are more profitable operations, and PSM contributes to reductions in costs related to maintenance, insurance, capital, and production.

It is also gaining traction here in Canada among various industries, governments and provincial regulators. It’s the focus of the Canadian Standards Association’s Z767 Process Safety Management standard, the proposed second edition of which was recently out for review. CSA Z767 is an established Canadian standard for PSM developed by a technical committee comprised of subject matter experts across sectors including oil and gas, mining, regulatory authorities, emergency response, chemicals, and safety consulting.

For the pellet sector, much of our risk lies in combustible dust. The recommendation from Integrating Process Safety Management into Canadian Wood Pellet Facilities that Generate Combustible Wood Dust, was the industry proceed with PSM implementation through a strategic long-term plan. You can read our short summary which includes links to resources and easy-to-use tools you can begin using in your operation today.

To support the ongoing development of the CSA Z767 standard from the perspective of the wood products manufacturing industry, Kayleigh Rayner Brown, MASc, P.Eng. (Obex Risk Ltd.), Bill Laturnus (BC Forest Safety Council), Gordon Murray (WPAC) and Fahimeh Yazdan Panah (WPAC) have joined the technical committee.

Operations are encouraged to contact Gordon Murray (gord@pellet.org) with questions about the vision and goals for PSM implementation.

To read the full article, click here.

The Wood Pellet Association of Canada (WPAC) and one of its members, Drax Group, recently had the pleasure of touring Todd McDonald, WorkSafeBC’s (WSBC) new head of prevention services, around Drax’s Williams Lake pellet plant.

One of the goals of WSBC is to foster the improvement of occupational health and safety in workplaces and communities and one of the ways they do that is by partnering with employers and workers in B.C. Todd’s recent visit on July 25 was an example of just that and an opportunity for our sector to highlight our commitment to safety, continuous improvement, and strong partnerships.

During the tour, we reflected on some of our major achievements such as critical control management implementation, inherently safer design research project and the great work of our belt dryer safety working group. WPAC also brought Todd and his team up to speed on our current initiatives such as the operator training program including the e-learning platform, process safety management implementation and combustible gas bowtie report and roll-out.

WPAC values our relationship with WSBC and their support of our safety initiatives. While we keep them up to date via meetings and communications there’s no replacement for boots on the ground opportunities at the plants to meet the people and see safety in action. A huge thanks to Liezl van Wyk, VP Northern Operations at Drax, and her team for their support and participation.

To learn more, click here.