The Wood Pellet Association of Canada (WPAC), BC Forest Safety Council (BSFSC), Dalhousie University, and DustEx Research Ltd., along with Obex Risk Ltd. as project technical lead, recently completed a research project to look at the implementation of process safety management (PSM) using the CSA standard Z767 Process Safety Management as the framework.

Around the world, process safety management (PSM) is becoming central to worker safety and managing risk. It can help prevent fires and explosions to protect personnel, operations, and production. Safer operations are more profitable operations, and PSM contributes to reductions in costs related to maintenance, insurance, capital, and production.

It is also gaining traction here in Canada among various industries, governments and provincial regulators. It’s the focus of the Canadian Standards Association’s Z767 Process Safety Management standard, the proposed second edition of which was recently out for review. CSA Z767 is an established Canadian standard for PSM developed by a technical committee comprised of subject matter experts across sectors including oil and gas, mining, regulatory authorities, emergency response, chemicals, and safety consulting.

For the pellet sector, much of our risk lies in combustible dust. The recommendation from Integrating Process Safety Management into Canadian Wood Pellet Facilities that Generate Combustible Wood Dust, was the industry proceed with PSM implementation through a strategic long-term plan. You can read our short summary which includes links to resources and easy-to-use tools you can begin using in your operation today.

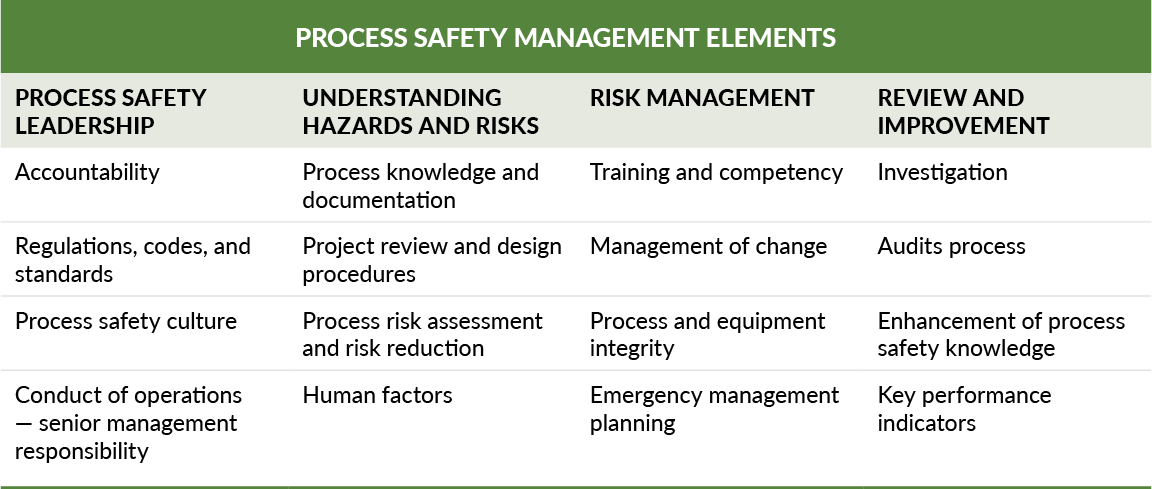

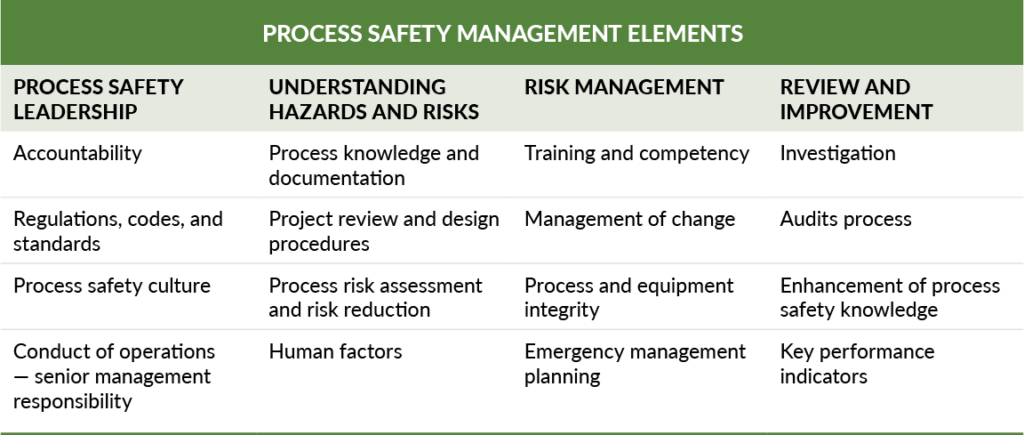

Each of the PSM elements described by CSA Z767 are present in the operations, but there are opportunities to develop formal documentation to fully implement each of the 16 PSM elements and close gaps to continuously improve the safety of operations.

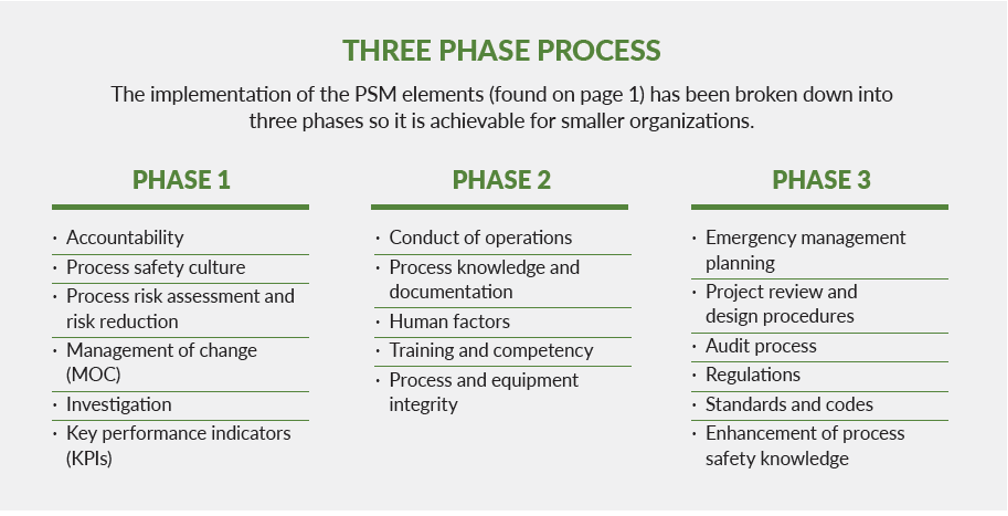

Overall, we found PSM element implementation can be broken down into phases 1, 2 and 3 to provide a pathway for implementation that is achievable for smaller organizations. Phase 1 focuses implementation efforts on high-priority elements that present the most potential to provide systemic changes in organizations and manage risk.

Caption: PSM implementation can be broken down into phases 1, 2 and 3 so it is achievable for smaller organizations. Phase 1 focuses on high-priority elements that have the greatest potential for systemic changes in organizations and manage risk. Source: WPAC

Numerous implementation tools have been collected and developed, including PSM gap analysis worksheets, industry best practices, informative factsheets, and an implementation strategy.

The outcomes of this project serve as a foundational framework for the wood pellet industry, as well as other small-to-medium operations in high-hazard industries, to implement PSM. This project was funded through a WorkSafeBC Innovation at Work grant (now Applied Innovation).

To support the ongoing development of the CSA Z767 standard from the perspective of the wood products manufacturing industry, Kayleigh Rayner Brown, MASc, P.Eng. (Obex Risk Ltd.), Bill Laturnus (BC Forest Safety Council), Gordon Murray (WPAC) and Fahimeh Yazdan Panah (WPAC) have joined the technical committee.

Operations are encouraged to contact Gordon Murray (gord@pellet.org) with questions about the vision and goals for PSM implementation.

This project was funded by WorkSafeBC under an Innovation at Work grant. The views, findings, opinions, and conclusions expressed herein do not represent the views of WorkSafeBC.

Kayleigh Rayner Brown, MASc, P.Eng. is with Obex Risk Ltd. and is the technical lead on this project.