Wood pellets are commonly used around the world, especially in Europe and Asia, as a substitute for coal in pulverized coal power plants. To produce energy with an industrial power generator, coal and biomass are either blended together in a process known as biomass co-firing, or coal is replaced entirely with wood pellets, which is known as dedicated biomass firing.

Whether used for co-firing or for dedicated firing, wood pellets are handled similarly to coal. Pellets are ground into dust using modified coal mills or hammer mills.

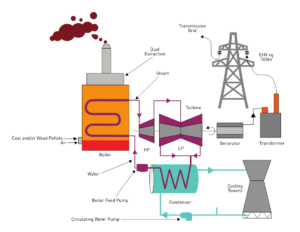

The dust is then mixed with air and blown through pipes which are connected to burners within a pulverized coal boiler. The dust-air mixture is ignited, acting much like a gas. Water is circulated inside the boiler in thousands of small tubes. The continuous flame boils the water within the tubes, creating steam.

The steam, under pressure, causes a turbine and generator to rotate. The generator uses a rotating magnetic field within a coil to create electricity which is fed to the electrical grid. Spent steam is passed through a condenser—essentially just pipes passing through cold water—and converted back into water which is circulated back into the boiler in a continuous process known as the Rankine Cycle.

Pellets are an easy substitute for coal. They can be easily ground into dust, have low moisture content (approximately 6 percent), handle easily and are comparable to coal with energy content of around 18 gigajoules per tonne.

Unlike coal, wood pellets may not be stored outside because they will disintegrate if exposed to rain. Pellets must be stored inside using silos, domes, or warehouse buildings. This means that pulverized coal power plants must be modified for wood pellet usage to add such storage, as well as separate conveying systems to transporting pellets from the storage to the milling process.

Read: The Status of Large Scale Biomass Firing from IEA Energy for more information on biomass firing and co-firing.

Converted pulverized coal boilers are not the only option for creating electricity from wood pellets at an industrial scale. Wood pellets are also used to create electricity by fuelling purpose-built circulating fluidized bed (CFB) boilers.

There are many CFB boilers in operation in Japan. At the bottom of the boiler furnace there is a bed of inert material, usually sand. The bed is where the wood pellets spread. Incoming air from nozzles under the bed lifts the bed material and wood pellets, keeping them in suspension. Combustion takes place in this suspended condition. Heat is used to raise the temperature of water in the boiler tubes and the remaining process creates electricity using the Rankine Cycle.

The main advantage of CFB boilers is that they can use a wider range of biomass fuels—most commonly a mix of wood pellets, wood chips, and palm kernel shells.

Global power producers are now in a race to commercialize carbon capture and storage (CCS) technologies. It is apparent that, coupled with CCS, biomass firing and co-firing provide one of the very few means of removing substantial quantities of carbon dioxide from the atmosphere.

Canadian wood pellets are exported around the world for industrial use in large-scale electric power plants. Our industrial markets include the United Kingdom, the Netherlands, Belgium, Denmark, Japan, and South Korea.

dive deeper

Stay Current

Sign up for email updates from WPAC