The Wood Pellet Association of Canada has partnered with the University of British Columbia on a four-year collaborative project to undertake comprehensive research related to wood pellet production, safety, logistics and commercialization of wood pellets. With funding from the Government of Canada, this research program brings together experts in the field of sustainable biomass, engineering and energy markets. The full compendium of research projects and reports is available at https://biomass.ubc.ca.

WPAC and UBC are partners in the Biomass and Bioenergy Research Group (“BBRG”). Some of our most recent projects include:

The BFN/WPAC research project is a four year project (2019-2023) funded by the federal government of Canada under the Canadian Agricultural Partnership. The BBRG is collaborating with the Wood Pellet Association of Canada (WPAC) and BioFuelNet Canada (BFN) in this project.

This research project is funded for four years (2019-2023) by federal government under the Canadian Agricultural Partnership. BBRG is collaborating with the Wood Pellet Association of Canada (WPAC) and BFN in this project. This project has four research tasks including:

- Preprocess and pelletize low-quality biomass and generate pellet production data using the newly purchased pilot-scale pellet machine, led by Dr. Hamid Rezaei

- Develop and compare supply chain scenarios and identify the most cost-efficient supply chain scenario considering the possibility of integration with existing grain and wood pellet supply chains, led by Dr. Mahmood Ebadian

- Develop best practices on safe handling and storage of pellets, led by Dr. Fahimeh Yazdan Panah

- Identify a clear commercial pathway to make marketable pellets from low-quality biomass resources a success, including developing quality certification, led by Dr. Shahab Sokhansanj (PI of the project) in collaboration with Wood Pellet Association of Canada (WPAC) and BiofuelNet

Best Practices for Managing Combustible Gas

Wood pellet plants produce syngas—a highly explosive mix of carbon monoxide, methane, hydrogen and other volatiles—during various stages of the pellet manufacturing process. This combustible gas is produced whenever biomass is subjected to high temperatures in a low-oxygen environment.

As a result of several recent syngas explosions, the Wood Pellet Association of Canada (WPAC)’s Safety Committee decided to produce an educational video to help operators minimize the risks associated with syngas.

Research Advancing Customer Relationships

Canadian pellet producers work with our customers to develop and implement key sustainability metrics and ensure that together, we are contributing to positive environmental outcomes. One excellent example of this type of partnership is Drax— a global green energy producer headquartered in the UK with operations in Europe and North America. Drax is also a major customer of Canadian wood pellet producers.

Committed to responsible fibre sourcing and transparency, Drax has detailed fibre sourcing and sustainability standards. The company backs these programs with evidence-based data and reporting, most notably in the company’s Catchment Area Analyses.

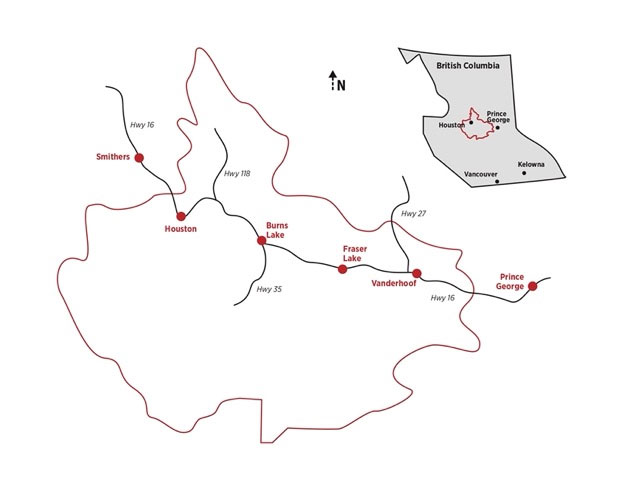

Drax has now posted the results of the Catchment Area Analyses for 2020—representing two-thirds of its global procurement—including a detailed report on Pinnacle Renewable Energy’s operations in Northwest British Columbia.

One of the main conclusions of the report is that pellet demand has had no influence on forest management practices other than more complete use of harvested trees, leading to reduced slash burning. Because the pellet mills primarily use mill residuals, and a minor amount of ground slash and low quality wood that would otherwise be burned or left to rot at roadside, harvest levels are not impacted by pellet production. The study also concluded that there were no negative effects on other participants in local forest industry.

Read more →