Research completed in cooperation between the Wood Pellet Association of Canada and UBC’s Biomass and Bioenergy Research Group found that hammer milling a heterogenous mix of feedstock consisting of unground forest residue, unground sawdust, ground forest residue and ground sawdust is possible without any loss of productivity.

Post-doctoral researcher, Dr. Jun Sian Lee conducted the study to understand the grindability and friability (the tendency of a solid substance to break into smaller pieces under stress or contact) of woody biomass such as sawdust and forest residue. The findings demonstrate that introducing a more heterogenous feedstock into a hammermill will not necessarily lower hammermill productivity. This would reduce the need to stratify the feedstock before hammer milling.

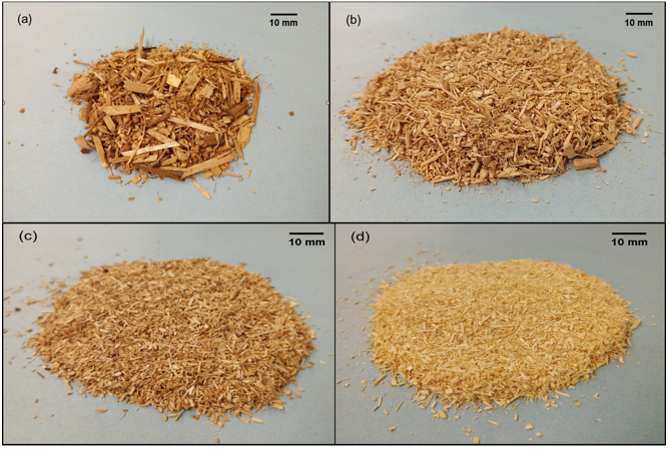

The conversion of raw biomass into usable feedstock involves a crucial preliminary step known as deconstruction, wherein biomass materials are processed to attain suitable particle sizes. Before grinding, 50 percent of the forest residue sample was larger than 4 mm whereas 50 per ent of sawdust sample was larger than 1 mm.

After grinding, the size distribution of the two samples (forest residue and sawdust) was similar highlighting the critical role of size reduction in making the material uniform in size. Although forest residue had much larger particle sizes than sawdust, their specific grinding energy consumption values were surprisingly similar. At 10 percent moisture content and a screen aperture size of 4 mm, hammer milling forest residue consumed 230 J/g energy while hammer milling sawdust consumed 200 J/g energy. Based on these results, hammer milling a feed with a mixture of dried woody biomass is a feasible approach.

To learn more about the study contact Fahimeh Yazdan Panah at fahimeh@pellet.org or Shahab Sokhansanj at Shahab.sokhansanj@ubc.ca.

Shahab Sokhansanj, Ph.D., P.Eng., FEC, FEIC, FCSBE, FASABE, is an Adjunct Professor, University of British Columbia.

Fahimeh Yazdan Panah, PhD, PMP and P.Eng, is the Director of Research and Technical Development, WPAC.

Jun Sian Lee, Ph.D, Post-doctoral fellow, Biomass & Bioenergy Research Group, University of British Columbia, Vancouver, Canada.