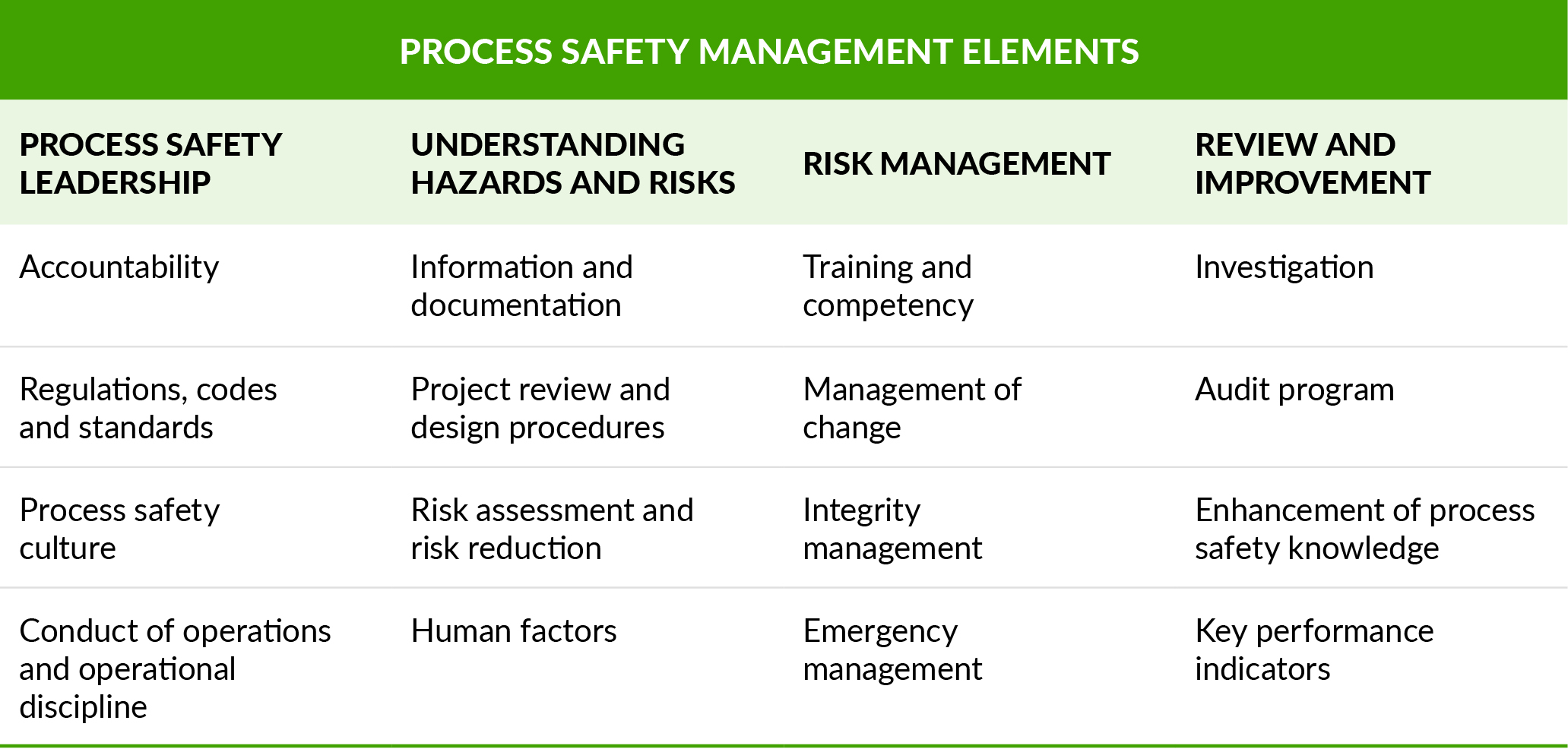

Around the world, process safety management (PSM) is becoming central to worker safety and managing risk. PSM implementation protects personnel, equipment, and production uptime, and is associated with lower maintenance cost, insurance and capital.

Disclaimer: A portion of these resources was developed through a project funded by WorkSafeBC under an Innovation at Work grant. The views, findings, opinions, and conclusions expressed herein do not represent the views of WorkSafeBC.